360° and macro lenses

Scope of 360 view lenses outer inspections

One of the most recurring needs in the machine vision industry is the complete inspection of an object with as few cameras as possible both for spatial and cost efficiency. These requests are common in almost every industry.

Opto Engineering designed a line of innovative 360° optics where one image is enough to view the top and all the sides of an object or the inside of a cavity. Most of these special optics are unique designs patented by Opto Engineering, with exceptional build quality and unmatched optical performance.

One of the most demanding requests from the machine vision market is to image the outer surfaces of a product with a single camera and lens pair. Outside inspections are often tackled by multi-camera systems, wherein a single object is imaged from several angles to form a complete view of the part. Unfortunately, due to the need for multiple camera setups, these types of systems can become quite costly and require more intensive integration from both the hardware and software perspective.

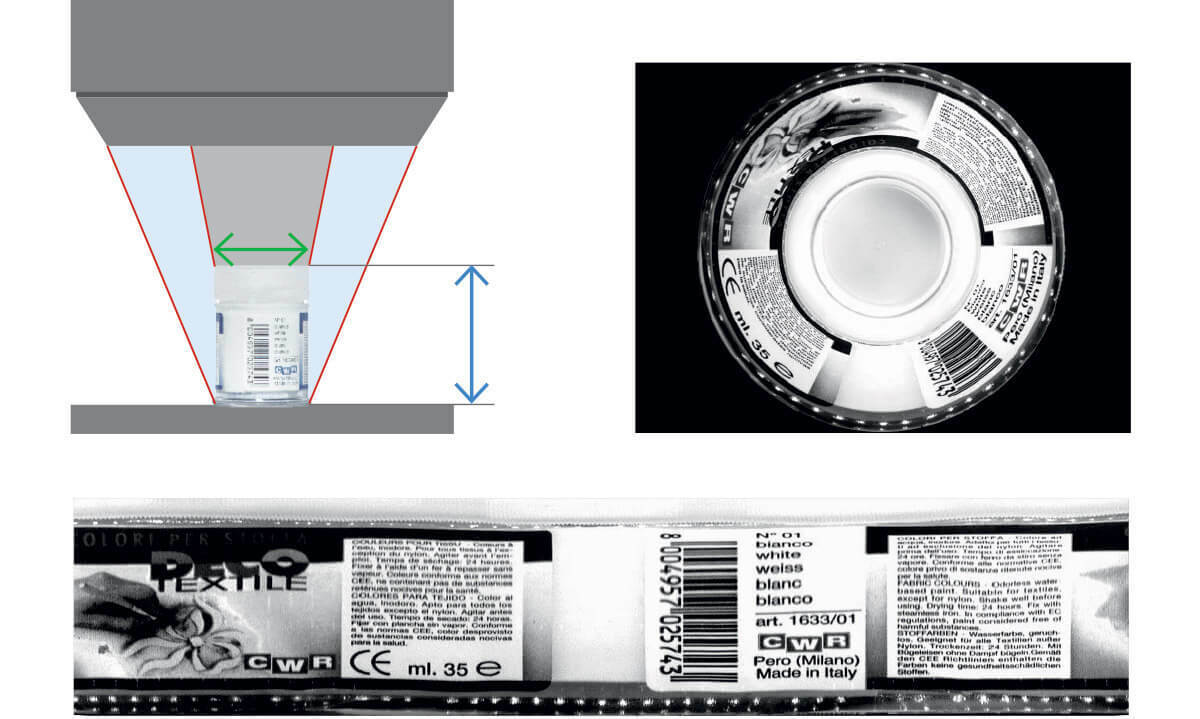

Pericentric and Catadioptric lenses are innovative products, designed to image both the top and side views of an object in a single image.

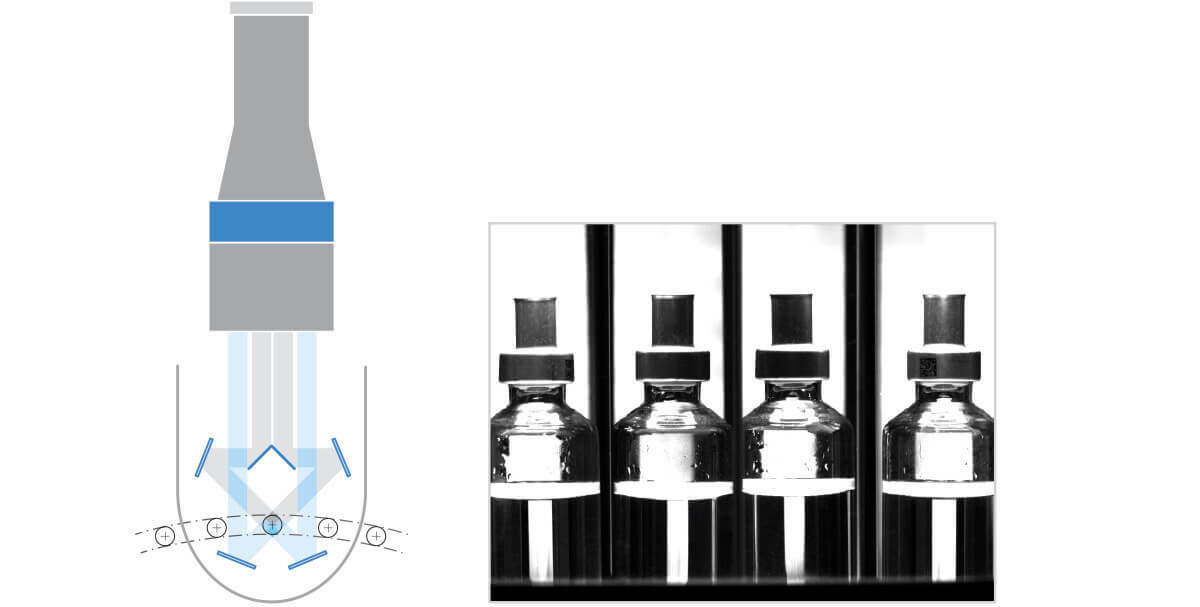

Since the camera is positioned at the top of the sample, these lenses are perfect for quick inline applications, such as the inspection of bottle caps or bottle necks, as well as OCR/OCV or Datamatrix, QR and barcode reading.

Scope of 360° View Lenses Inner Inspections

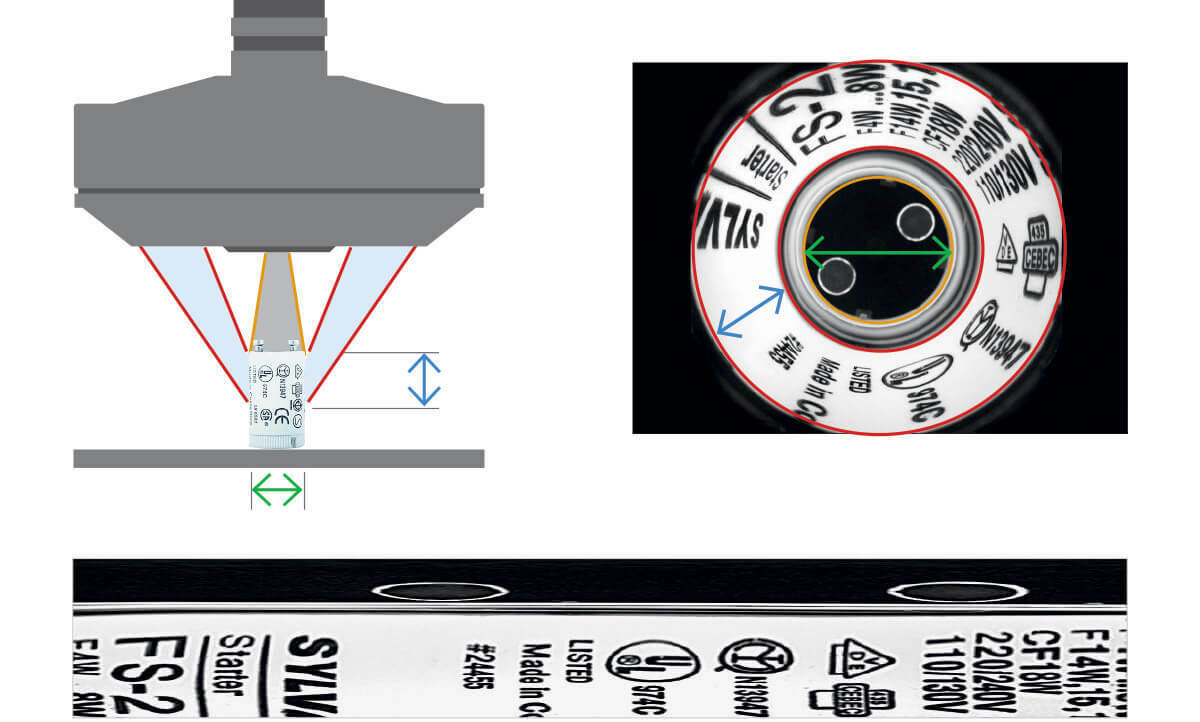

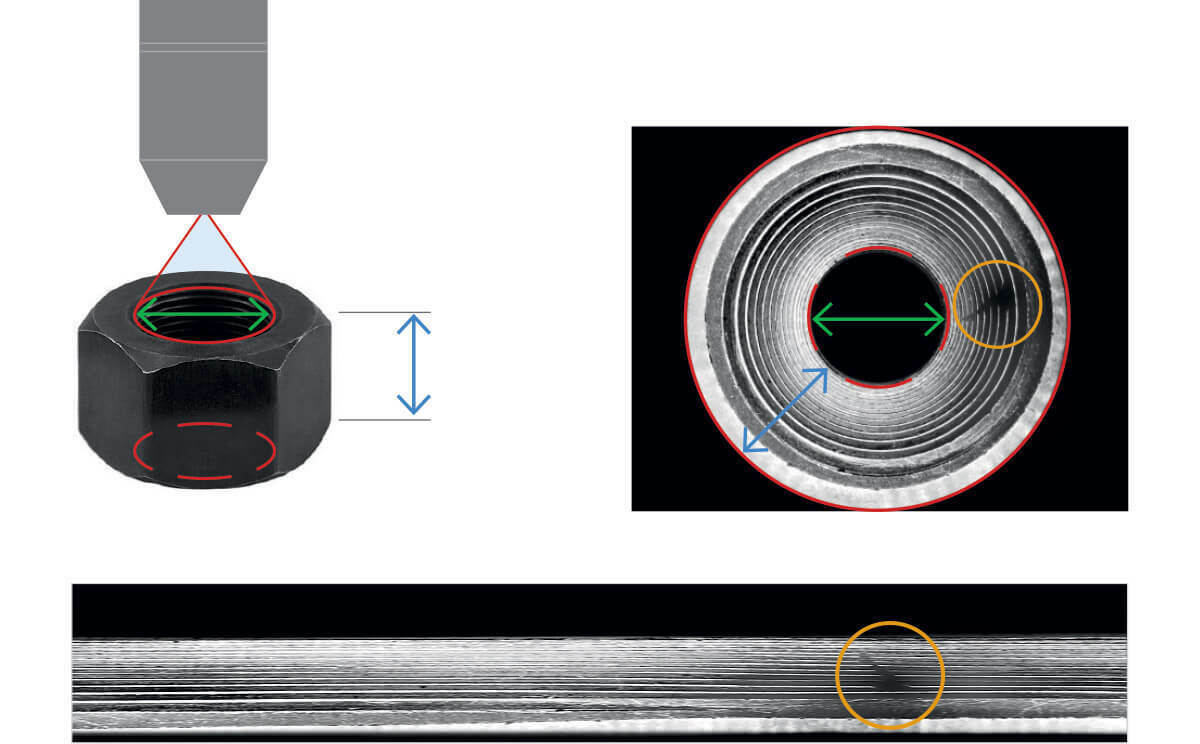

A common challenge faced by machine vision engineers is the inspection of hollow objects such as engine parts, containers, and tubes. In an application where the goal is to inspect defects along a cavity’s walls, standard lenses are often not capable of providing adequate coverage or resolution.

This is where Opto Engineering’s inner inspection lenses can be very powerful. We have developed three distinct lens series for these types of applications – the PCBP (boroscope), the PCHIL (pinhole), and the HC (hypercentric).

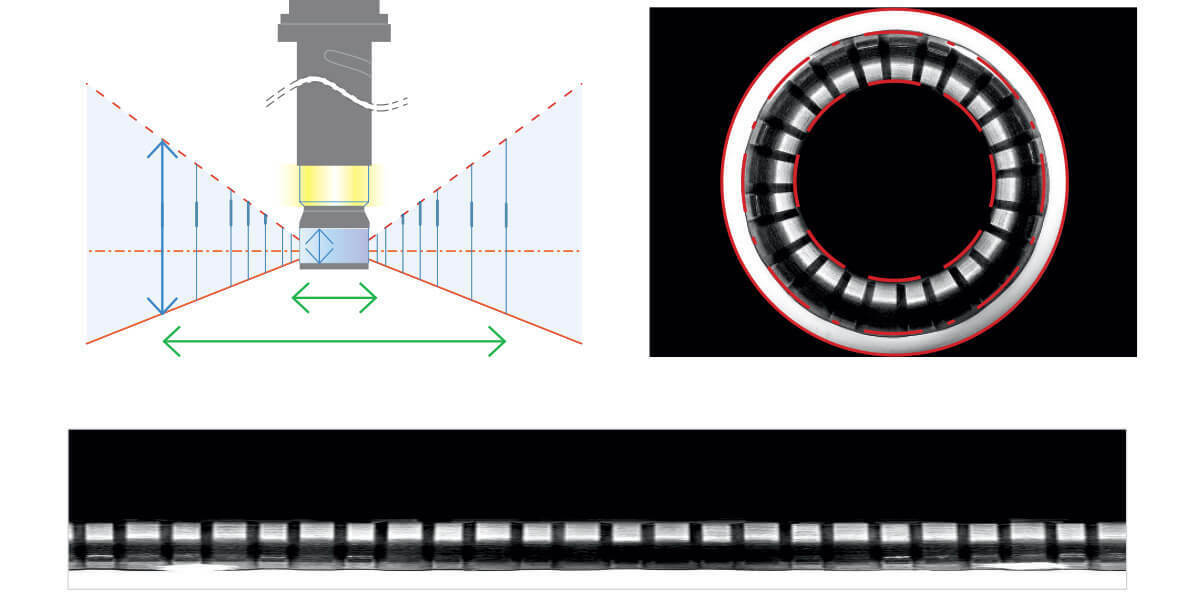

Starting with the PCBP: designed to be introduced into a hollow object, our PCBP incorporates a conical mirror that allows the user to capture a 360-degree view of the cavity walls. Built-in illumination keeps the device very compact and makes it suitable for simple 3D applications by means of panoramic triangulation techniques.

Alternatively for high throughput applications or for those where the introduction of a lens is not ideal, the PCHIL and the HC series can image both the bottom of hollow objects and their vertical walls from above.

Applications that often benefit from these 360 degree internal inspection lenses include surface defect detection, presence/absence, and alignment identification applications. These types of applications are commonly found in the automotive, pharmaceutical, cosmetics, medical, and beverage industrial sectors.

Scope of 360° view lenses: Multi-view applications

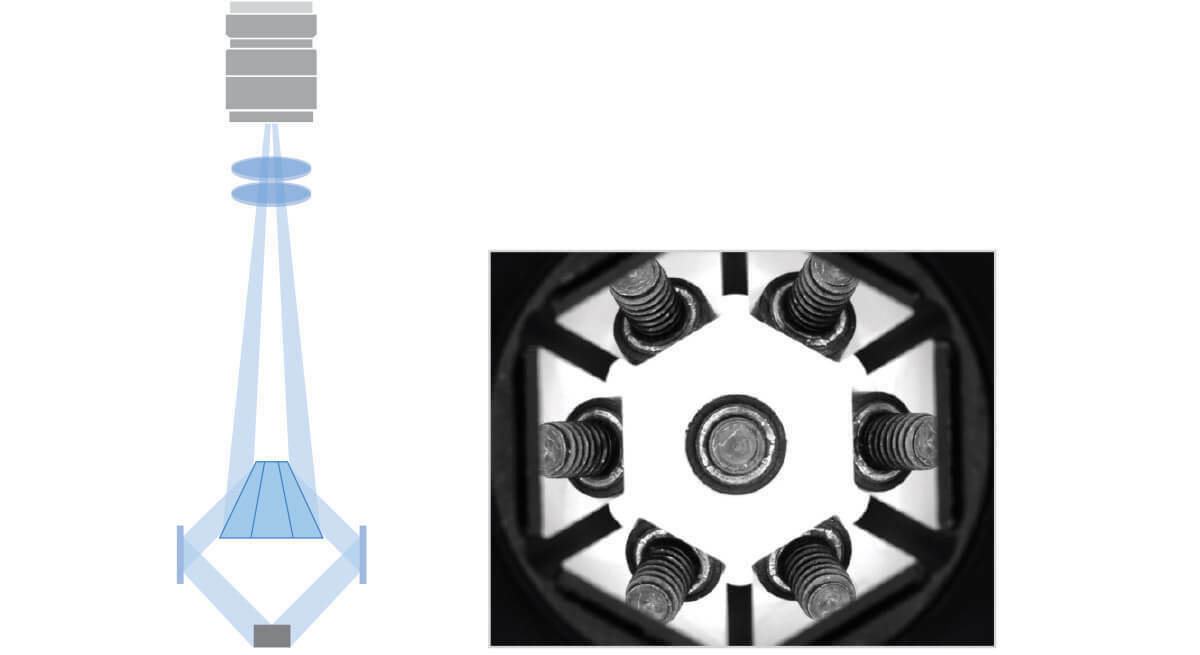

Another scope of 360° view lenses is to obtain a multi-view image for many demanding applications. Pericentric and Catadioptric lenses are great choices when 360° inspection is needed without multi-camera systems. For applications focused on samples that do not feature axial symmetry, Opto Engineering multi-view lenses can provide a user with a full 360-degree view through optical mirrors. By introducing mirrors and prisms on the optical path, the Field of View is divided into multiple views of the product.

The PCMP and TCCAGE lens series integrate telecentric optics, leveraging the low distortion and lack of perspective error of telecentrics to capture high-precision images that can be used for both measurement and inspection applications.

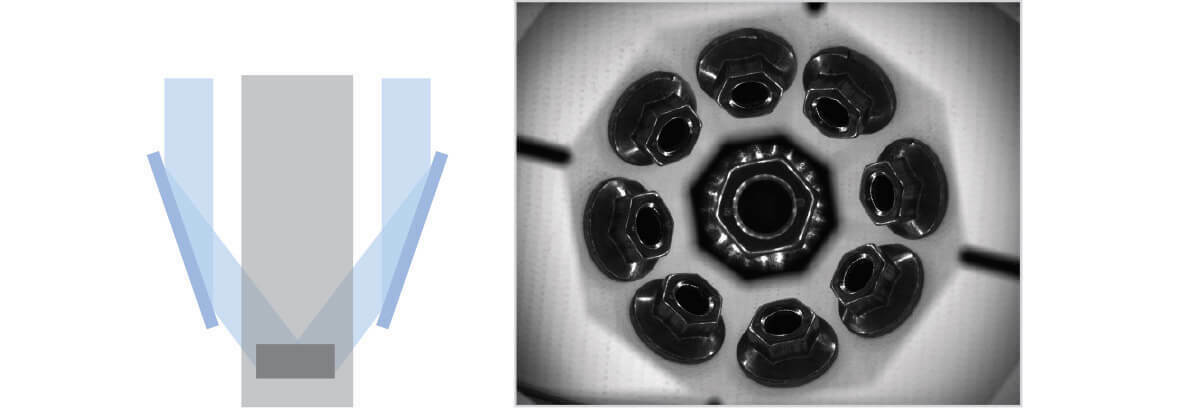

The TCCAGE is an integrated optomechanical system designed to fully inspect and measure parts from the side without any need of rotation. Four 90-degree views of an object are provided by a bi-telecentric lens through an array of mirrors. Two different illumination devices are built into the system to provide either backlight or direct part illumination.

The PCMP series features multi-image lenses designed to completely measure and inspect objects by generating six different lateral views provided by an array of mirrors interfaced to a bi-telecentric lens. The lens integrates diffused LED illumination optimized for this specific assembly.

PCPW optics provide eight different views of the side and top surfaces of an object. The wide angle of view (45°) enables the inspection of the side features of an object that otherwise would be impossible to acquire with a single camera. Both an object's external walls and its top can be imaged at the same time, while internal surfaces of hollow objects can be fully inspected from the outside.

Typical application examples are 3D inspection of an electronics part on a PCB board, Data matrix reading on a pharmaceutical vial or alignment checking on syringe needles.

360° optics

Many machine vision applications require a complete view of an object surface since many features to be inspected are located on the object sides rather than on top. Most cylindrical objects such as bottles and containers, as well as many kinds of mechanical parts, require an inspection of the side surfaces to detect scratches and impurities or to read barcodes or, again, to ensure that a label has been printed correctly.

In these cases, the most common approach is to use multiple cameras (usually 3 or 4) in order to achieve several side views of the part, in addition to the top view. This solution, besides increasing the cost of the system, often creates a bottleneck in the system performances, since the electronics or software must process different images from different cameras simultaneously. In other cases, vision engineers prefer to scan the outer surface with line scan camera systems.

This approach also shows many technical and cost disadvantages: the object must be mechanically rotated in the FOV which also affects the inspection speed; moreover, line-scan cameras require very powerful illumination. Also, the large size of linear detectors increases the optical magnification of the system, thus reducing field depth.

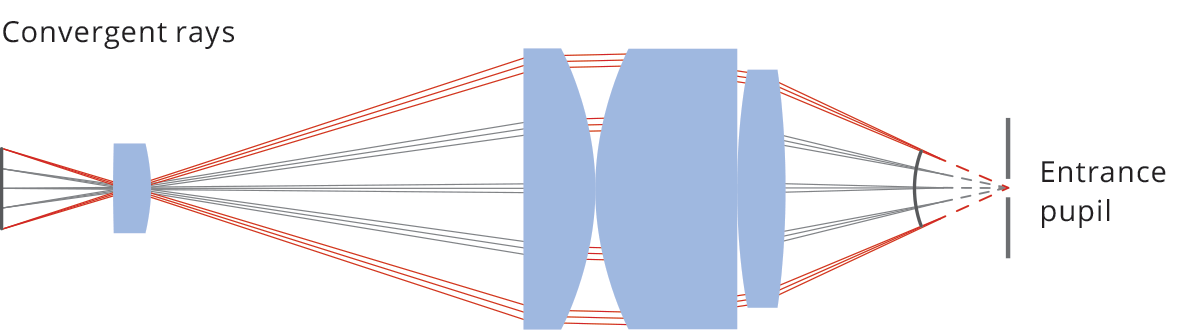

The 360° optics category encompasses different optical solutions that capture rays diverging from the object (see Fig. 37), thus imaging not only the object surface in front of the lens but also the object’s lateral surface (see optical diagram below).

The following images illustrate the working principle applied to a pericentric lens (PC), a catadioptric lens (PCCD), a pinhole lens (PCHI) and a boroscope lens (PCPB). Other 360° optical solutions combine telecentric optics and mirror arrays, allowing you to get a complete view of a sample with just one camera (TCCAGE, PCPW, and PCMP series).

Macro lenses

Macro lenses are fixed focal length lenses whose working distance is comparable to their focal length. The recommended working distance from the object is usually fixed, hence macro optics are usually described by their magnification.

Since macro lenses are specifically designed to image small and fixed FoVs, they tend to have extremely low geometrical distortion. For example, the distortion of Opto Engineering® MC series lenses range from <0.05% to <0.01%.