ITALA® cameras: precise rotors and stators inspection

Case history Delta Visione (English)

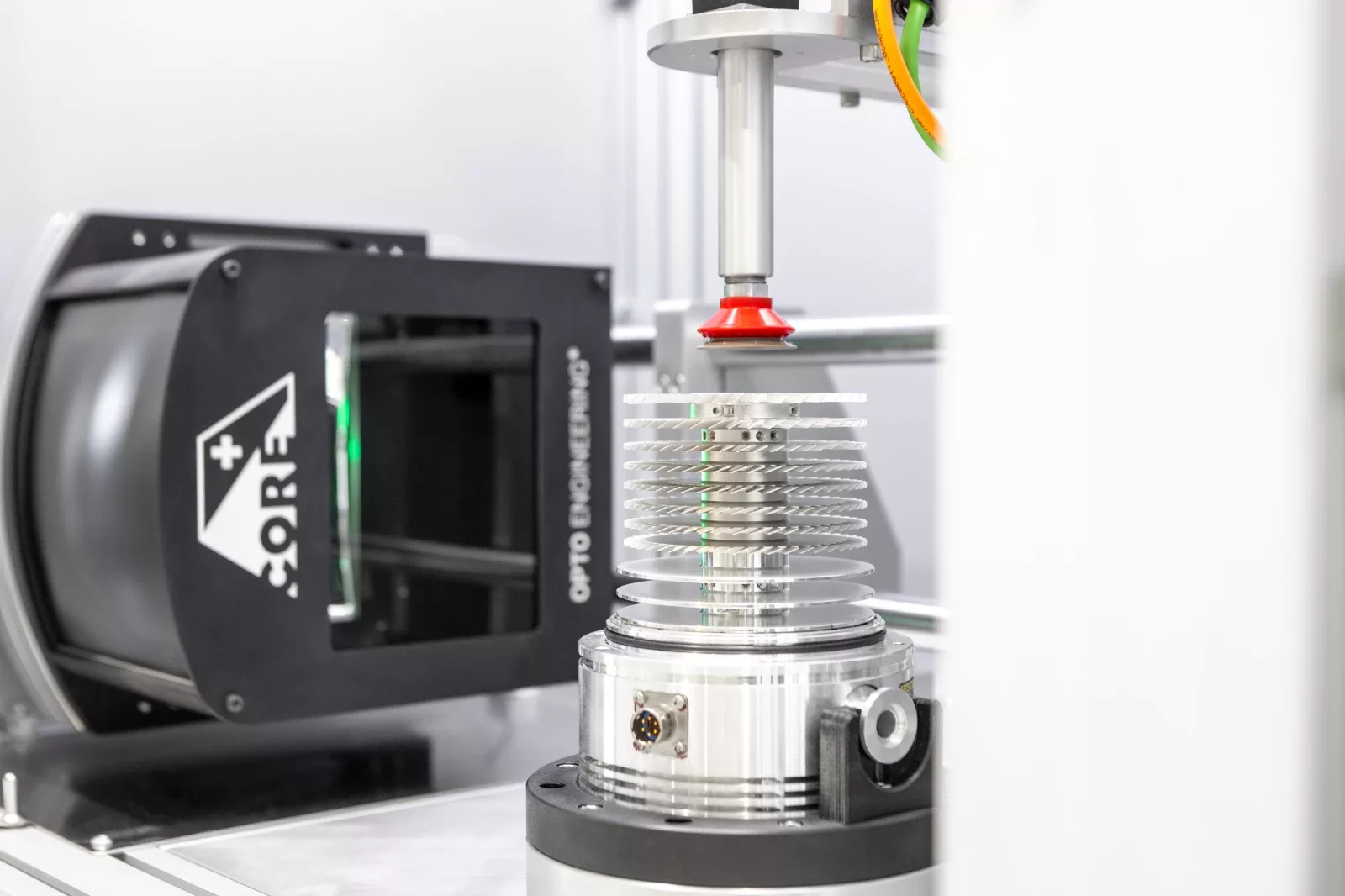

Delta Visione has developed an offline system for the 360° inspection and measurement of a precision mechanical apparatus consisting of a rotating rotor and stator performing up to 160 measurements in a single inspection with an accuracy of 0.02 mm.

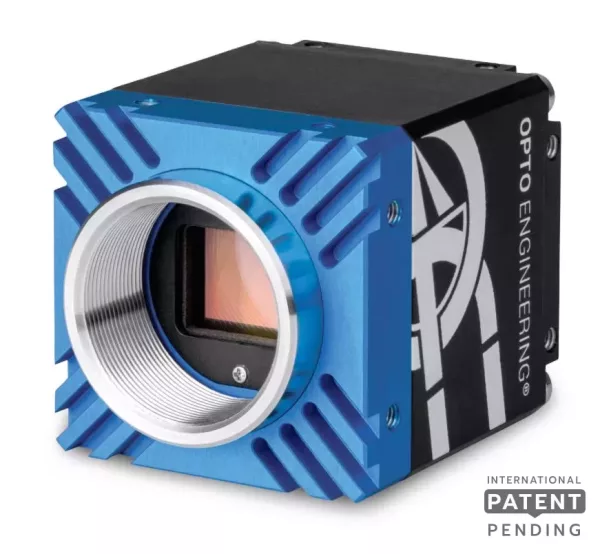

Delta Visione inspection and measurement system integrates an ITALA GigE area scan camera featuring 31,5MP in APS-C format combined with a TC10M144-J high-resolution telecentric lens and a LTCLCP144-G telecentric illuminator by the patented CORE PLUS series.

The work cycle involves the intervention of an operator who communicates with the machine via the HMI.

The case

The precision and reliability of Opto Engineering's ITALA cameras ensure superior performance in inspection and measurement applications. In this application, ITALA® is used in an offline system for the 360° inspection and measurement of a precision mechanical apparatus consisting of a rotating rotor and stator.

Why ITALA® cameras?

Opto Engineering selects the best components from its product range to provide perfect integrations that can be configured to meet the most demanding requirements for resolution, precision and accuracy.

Delta Visione recommends ITALA® cameras because of their performances, their robust design and excellent image quality that is particularly smooth.